- Adjustable cutting envelope

- Best in class material optimization (Dynamic Optimization™)

- Advanced dust collection

- Pack/bundle and panel list capability

- 5-piece door panel optimization

- Onboard diagnostics

- Part list downloading

- Downloading patterns

- Configurable to push up to 2,100 lbs.

- Inkjet and Label Printing (Option)

- Crayon Defect Marking (Option)

- Part List Download (Option)

FINANCING AVAILABLE!

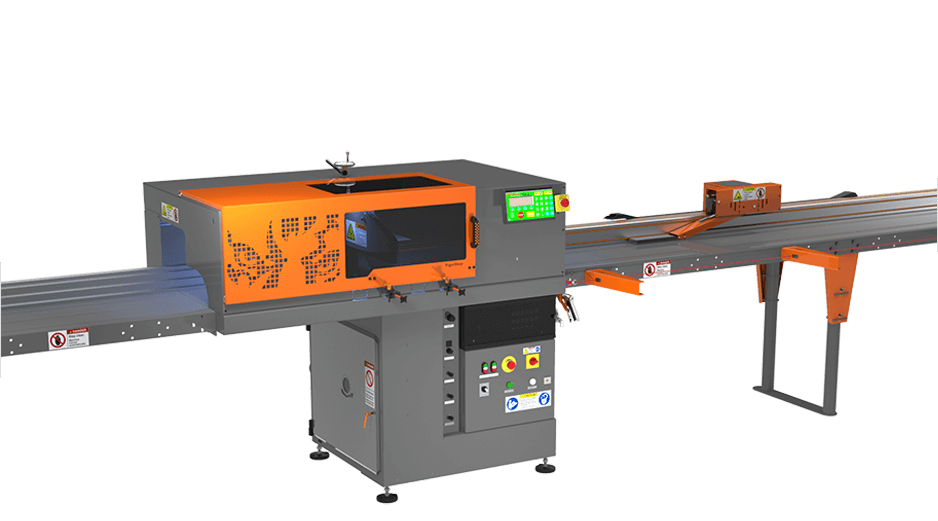

the defecting, optimizing saw for any shop

FEATURES

THE TIGERSAW ADVANTAGE

FULL AUTOMATION

Currently, most component cutting is done manually with a tape measure or manual stops. This is slow and inaccurate. TigerSaw 1000 greatly increases throughput while achieving maximum yield, without the need to hire additional operators.

FUNCTIONALITY OF HIGH COSTING SAWS, WITHOUT THE PRICE TAG

TigerSaw 1000 offers all of the features and benefits of saws costing 2 to 3 times as much. It comes with an adjustable cutting envelope so you can set the envelope to the needed width of the material you are cutting, whether single piece flow or pack. TigerSaw 1000 can handle large pack loads up to 2,100 lbs. when using the HeavyDuty 2 pusher.

DYNAMIC OPTIMIZATION TUNED TO YOUR SHOP

TigerSaw 1000’s Dynamic Optimization software gives you the best yield by determining the optimal cutting order from your parts list. TigerSaw 1000’s Crayon Defect Marking allows you to remove defects (knots, wane, discoloration) from your material in-house, for even greater savings.

SAFE AND EASY TO USE

TigerSaw 1000 is available with table configurations that are flat or tilted 10 degrees. It is easy to install and maintain, comes with a ton of built in safety features, and is simple for operators to use.

DROP A GRADE AND SAVE

Most shops buy expensive defect-free material to get the best yield possible. With TigerSaw 1000, defecting your own material is faster and easier than ever before. Drop an entire lumber grade, save on your material bill, and quickly defect material in-house. Use a UV Crayon to mark knots, wane, and discoloration. TigerSaw 1000 will cut around the defects and optimize clear material while running through your cut list. Combined with Dynamic Optimization™, TigerSaw 1000 gives operators the ability to cut around defects while achieving the maximum yield. In most cases, shops buying FAS or SEL grade are able to downgrade to #1 Common while still achieving the same yield. This is typically a 20% to 30% savings in material cost.

PRECISION GROUND TABLES

Tables on saws can be flimsy and uneven, causing inaccuracies. TigerStop uses precision ground tables and fences on the TigerSaw1000 for stability and accuracy in the toughest shop environment. Tables can be configured flat to accommodate autoloading, or tilted 10 degrees to ensure square cuts.

EASY DIAGNOSTICS

Pneumatic adjustment points are in the front of the machine where they can be easily reached by the machine operator. All i/o is front and center on the machine allowing for easy troubleshooting.

BENEFITS

ADVANCED DUST COLLECTION

Advanced airflow control technique using baffles to direct the flow of air generated by the saw blade. This provides a cleaner environment for improved inkjet printing quality and part quality.

CRAYON DEFECT MARKING

Many shops buy higher quality material to avoid defecting because defecting is difficult and time-consuming. TigerSaw 1000 makes it easy. Operators use a UV Crayon to mark defects in the material. TigerSaw 1000 cuts around those defects and optimizes the clear material while cutting parts. When defecting and optimizing in-house, shops can downgrade to lower cost lumber and retain the same high quality. See you lumber bill shrink with TigerSaw 1000.

PROCESS/PACK BUNDLES

Using a high capacity pusher, like the TigerTurbo or HeavyDuty 2, along with a larger cutting envelope means you can process packs and bundles. Cutting bundles dramatically increase throughput (i.e. cutting ten parts at once increases production tenfold). TigerSaw 1000’s adjustable cutting envelope can accommodate pack sizes from 6in x 6in to 1in x 16in envelopes and the HeavyDuty 2 can push loads up to 2,100 lbs.

5-PIECE DOOR PANEL OPTIMIZATION

Processing random width lumber for seamless panel glue-up is difficult and time-consuming. Using TigerSaw 1000’s Dynamic Optimization you can processes panel lists optimized for width.

MIX AND MATCH CLAMPING

TigerSaw 1000 offers 3 clamping styles that can be used separately or together to deliver the exact clamping solution you need. Optional pneumatic horizontal clamping, as well as passive spring clamping, allows the operator to easily hold parts regardless of whether they have profiles on the clamping surface.